RINGWALL DESIGN: Use Following Weight Values for Materials 490lb/ft3 110 lb/ft3 150 lb/ft3 50 lb/ft3 Compression or Tension Due To Moment: Seismic Base Shear: UnAnchored Longitudinal Compressive Stress 7000 / 6 Allowable Longitudinal Compressive Stress GHD2/t2 1.255 * 106 = Fa=106 (t) / D = Anchorage Not RequiredįOUNDATION DESIGN: Max. Reistance to Overturning:( E.4.1) API 650 W L = 7.9tb Fby G H DATA GIVEN: Seismic Zone Zone Coefficient Importance Factor Diameter of Tank Height of Liquid Content (Design) Shell Height Design Specific Gravity Thickness of Bottom PL Under Shell Yeild Strength of Bottom PL Weight of Shell Weight of Roof + Live Load = 107.4 + 210.4 PI()/4(94.5)2 (44.5)(.79)(62.4) Weight of Product

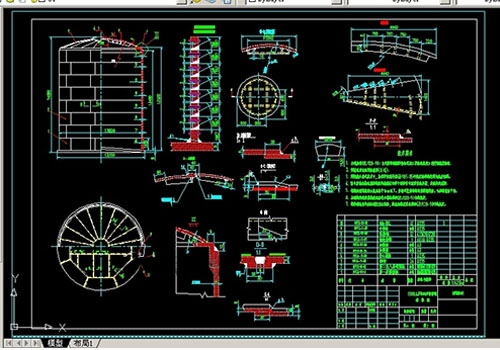

Td =td / tt = 2.6(D)(H-1)/(St) td = Miniumum shell thickness, in inches D = Normal tank diameter, in feet H = depth of tank, in feet G = design Specific gravity of liquid Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress 516-60 Hydro Test CA = Corrosion Allowance For Fifth Course 516-60 Plateĩ4.5 8 1 21,300 0.85% 24,000 0.0625 0.2500Īnnular Bottom Plate Thickness D = Diameter in Feet H = Height in Feet V = Volume in Cubic FeetįOUNDATION DESIGN: Per API 650 (Appendix E) Tank is unanchored, use equations pertaining to unanchored tanks, for seismic loading. Td =td / tt = 2.6(D)(H-1)/(St) = td = Miniumum shell thickness = D = Normal tank diameter, in feet H = depth of tank, in feet G = design Specific gravity of liquid Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress 516-60 Hydro Test CA = Corrosion Allowance For Fourth Course 516-60 PlateĠ.2365 inches 94.5 18 1 21,300 0.85% 24,000 0.0625 0.2500 Td =td / tt = 2.6(D)(H-1)/(St) td = Miniumum shell thickness, in inches D = Normal tank diameter, in feet H = depth of tank, in feet G = design Specific gravity of liquid Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress 516-60 Hydro Test CA = Corrosion Allowance For Third Course 516-60 PlateĠ.209 50.00 28 1 21,300 0.85% 24,000 0.0625 0.3750įileName: _office WorkSheet: Steel DesignĪPI 650 Design Calculations Shell Design : td = 2.6(D)(H -1)(G)/Sd= Td =td / tt = 2.6(D)(H-1)/(St) = td = Miniumum shell thickness, in inches =ĭ = Normal tank diameter, in feet = H = depth of tank, in feet = G = design Specific gravity of liquid = Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress516-60 Hydro Test CA = Corrosion Allowance (Includes Corrosion Allowance) G = design Specific gravity of liquid Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress 516-60 Hydro Test CA = Corrosion Allowance Miniumum shell thickness, in inches, td = td / tt = 2.6(D)(H-1)/(St) td = 0.224 in.

#Api 650 tank design full

Fixed cone roof with internal floating roof.ĭesign Wind Velocity % Inspection Req'd ? Full of Water lbįROM ( BOTTOM COURSE) PLATE TO (TOP COURSE) PLATE td = 2.6(D)(H -1)(G)/Sd= Items marked with an asterisk (*) to be completed by Vendor/Fabricator.Ģ. Internals (attach separate sheet, as req'd):ġ.

#Api 650 tank design code

API API APIĤ5 Code (as appl.): 46 Design Specifications: 47 Tank Insulation ? 48 Insulation Type: 49 Fireproofing ? 50 Remarks Operating Temperature Design 30 Flash Point (Closed Cup) : ✯ Operatingģ1 Negative Pressure 32 Positive Pressureģ3 (Hydro)test Pressure expressed in Psig 34 Minimum Fluid Temperature 35 Maximum Fluid Temperature 36 Emergency Vacuum Design ? STORAGE TANK SPECIFICATION (English Units) Project No.ĬRUDE OIL 27 Fluid Stored : This Tank Service is considered: 28

0 kommentar(er)

0 kommentar(er)